Filamentous fungi is present in all types of ecosystems around the world. They mostly develop as a network of cells called hyphae. Organelles called vacuoles are responsible for nutrient storage as well as degradation of redundant organelles. They secrete primary metabolites for own metabolism while secondary metabolites contribute towards defense (antibiotics) or attachment (hydrophobins). Because of this, various fungal species are very important in fields like biotechnology, medicines, food production, and enzyme manufacturing, among others.

The amazing AI-based analysis solution provided by HS Analysis GmbH is based on strategies that incorporate objective analysis, which uses facts and evidence to draw conclusions from data without the use of subjective viewpoints or preconceptions, ensuring consistency and repeatability.

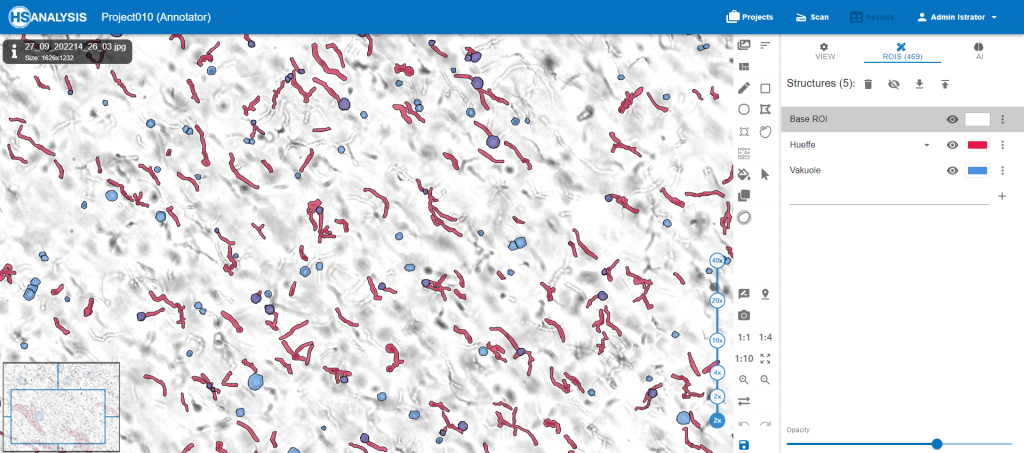

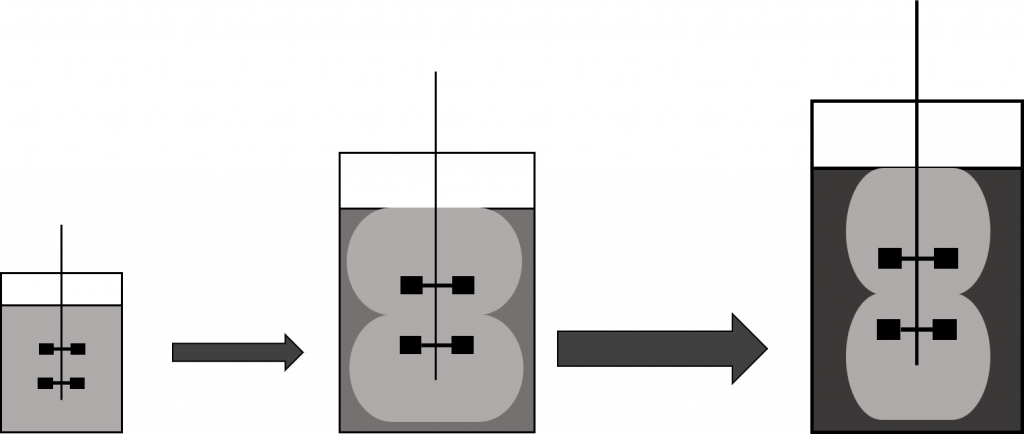

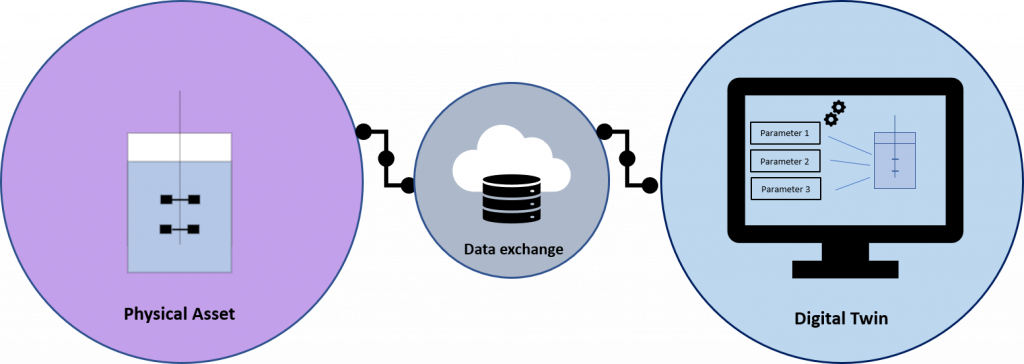

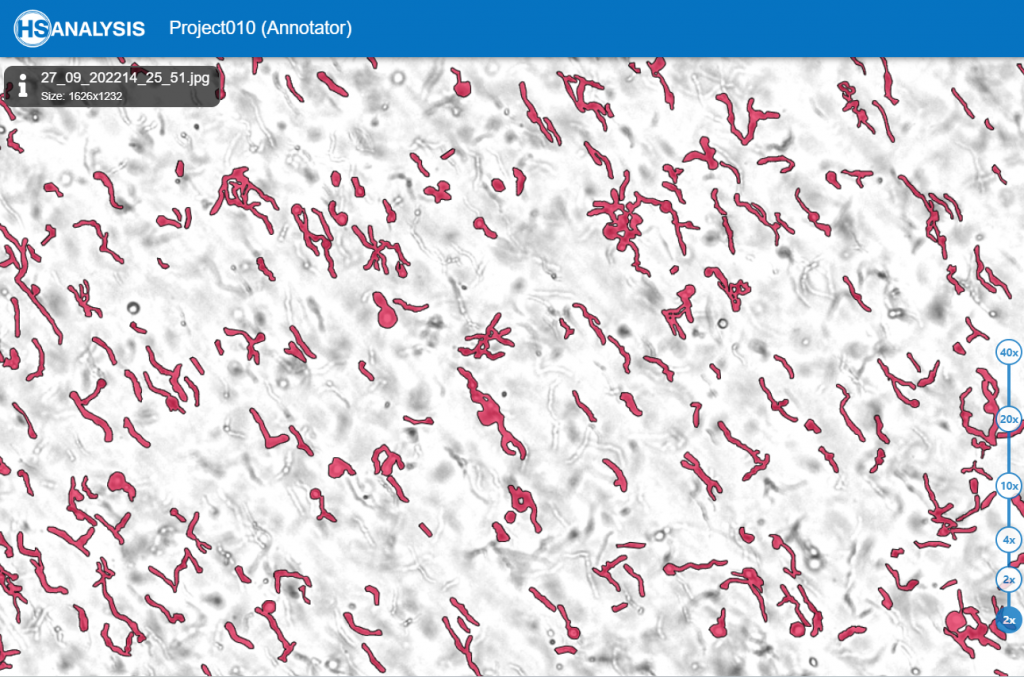

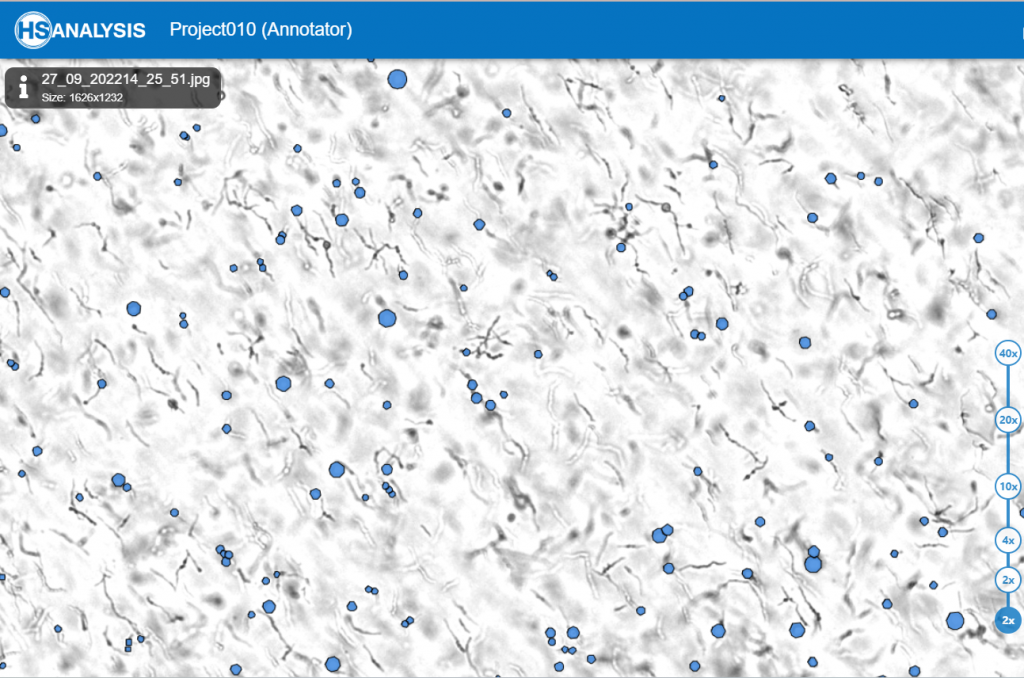

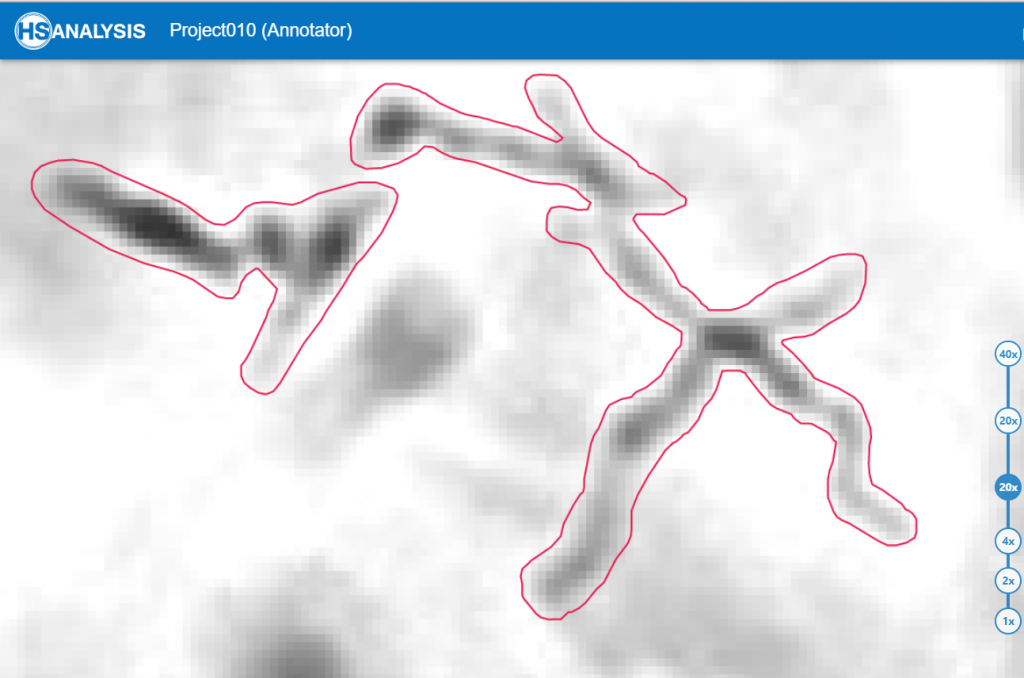

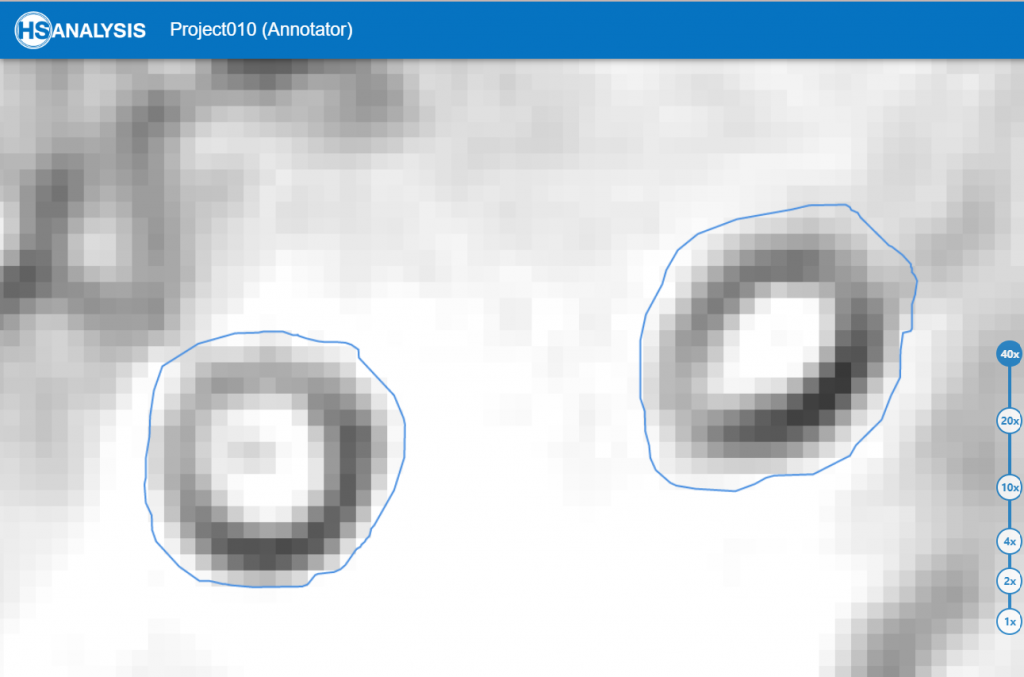

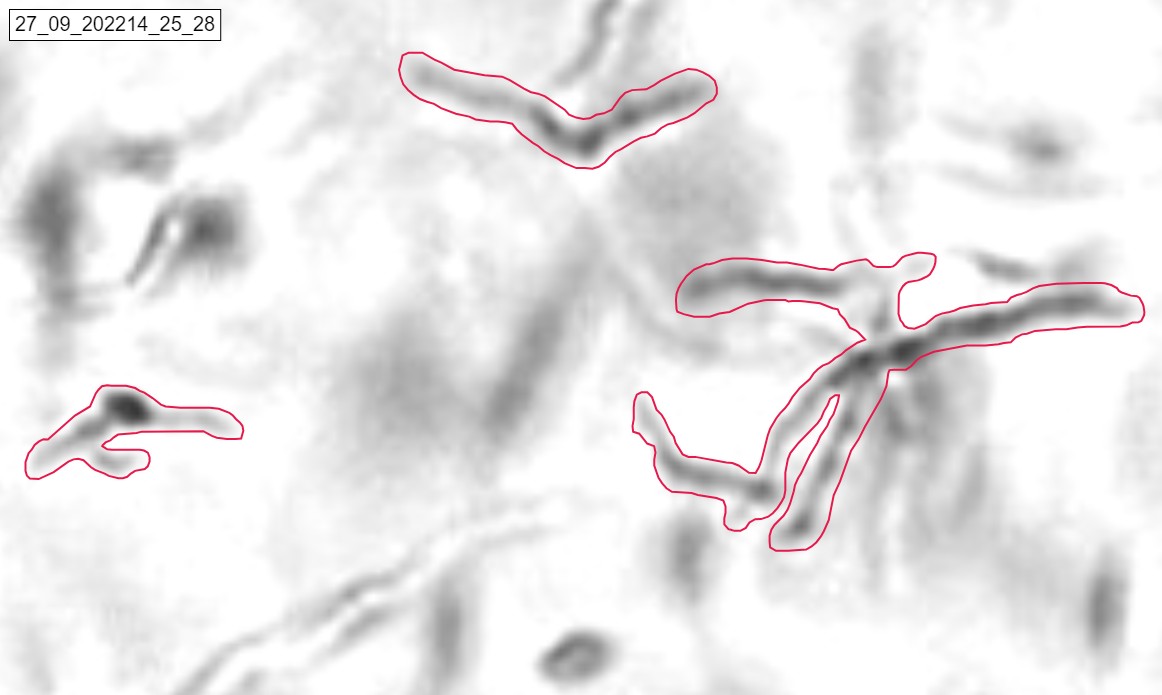

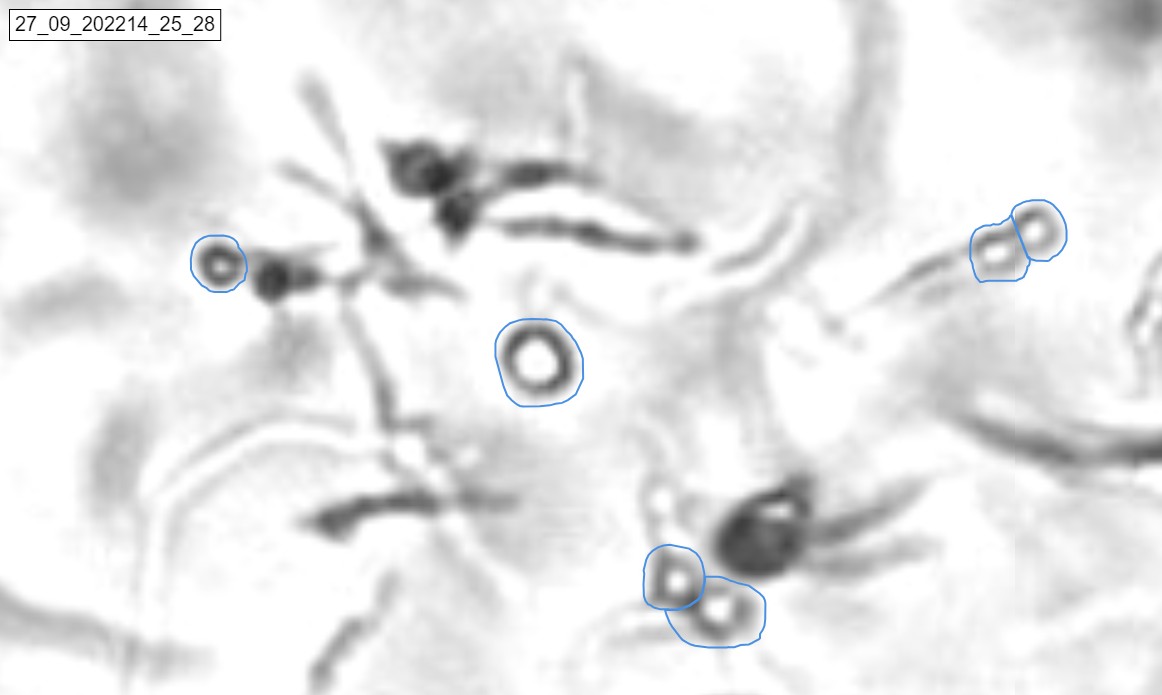

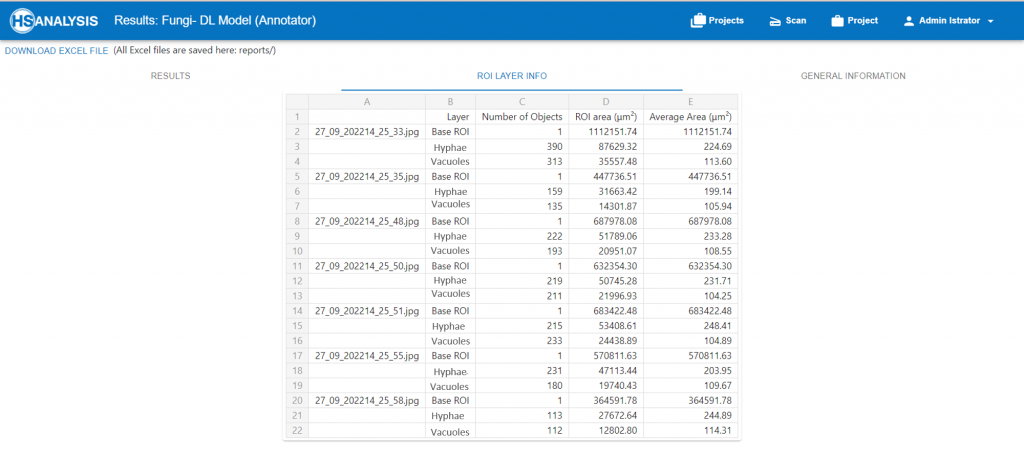

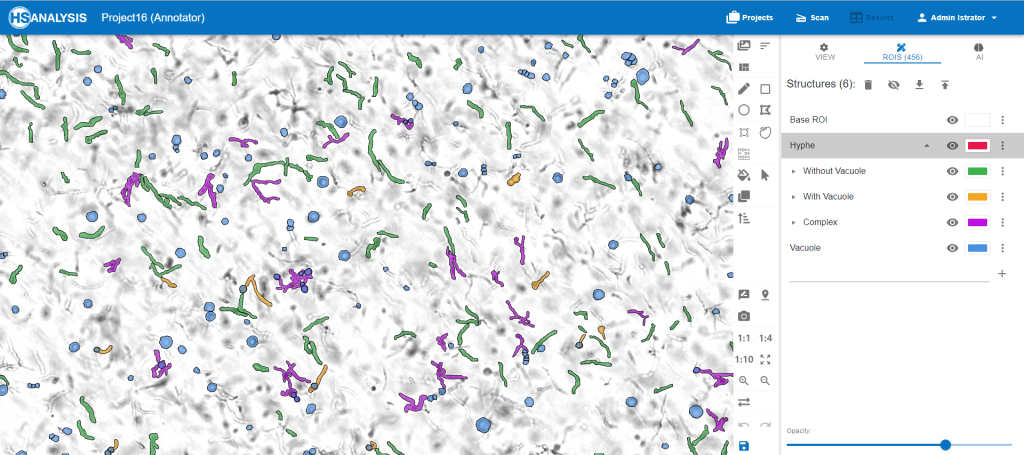

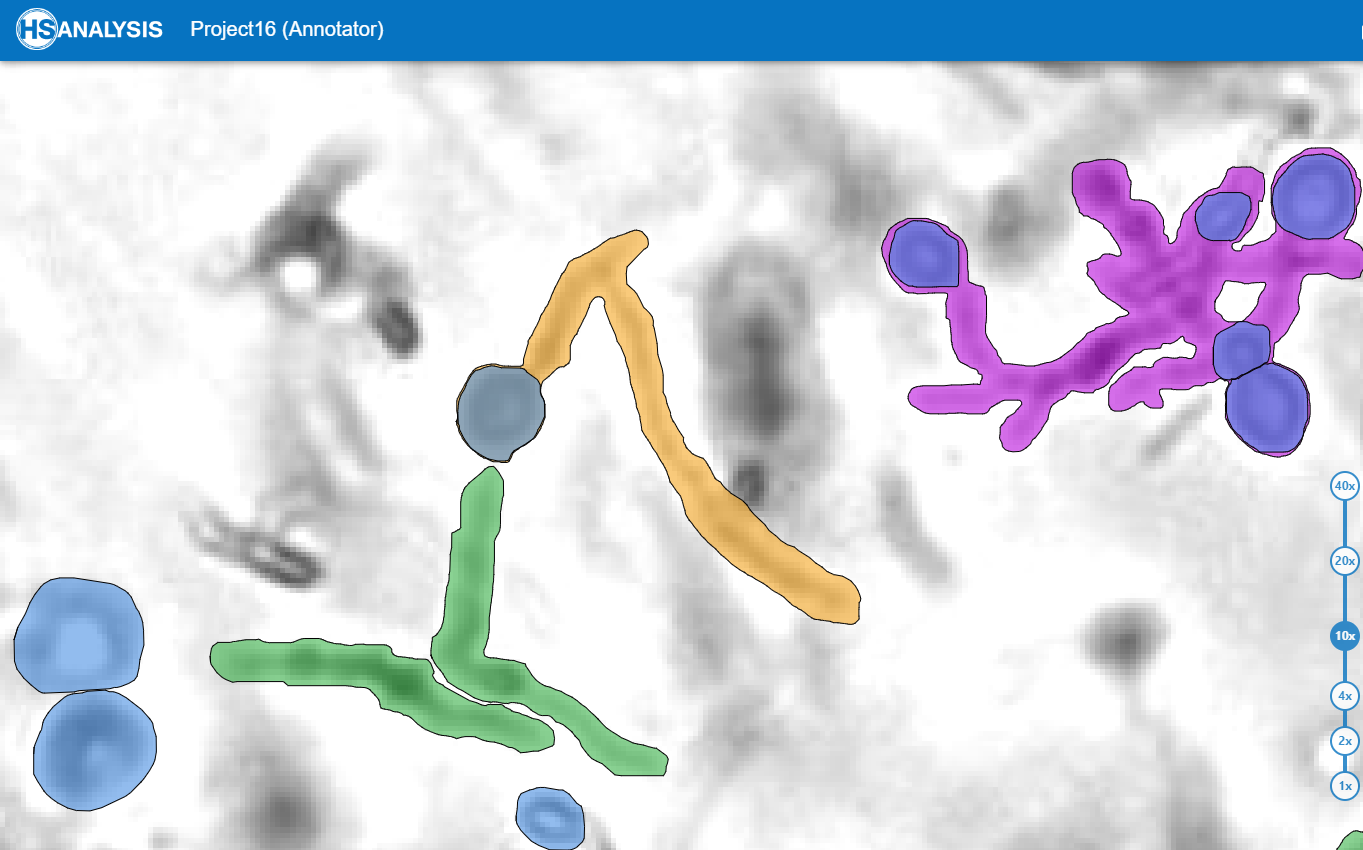

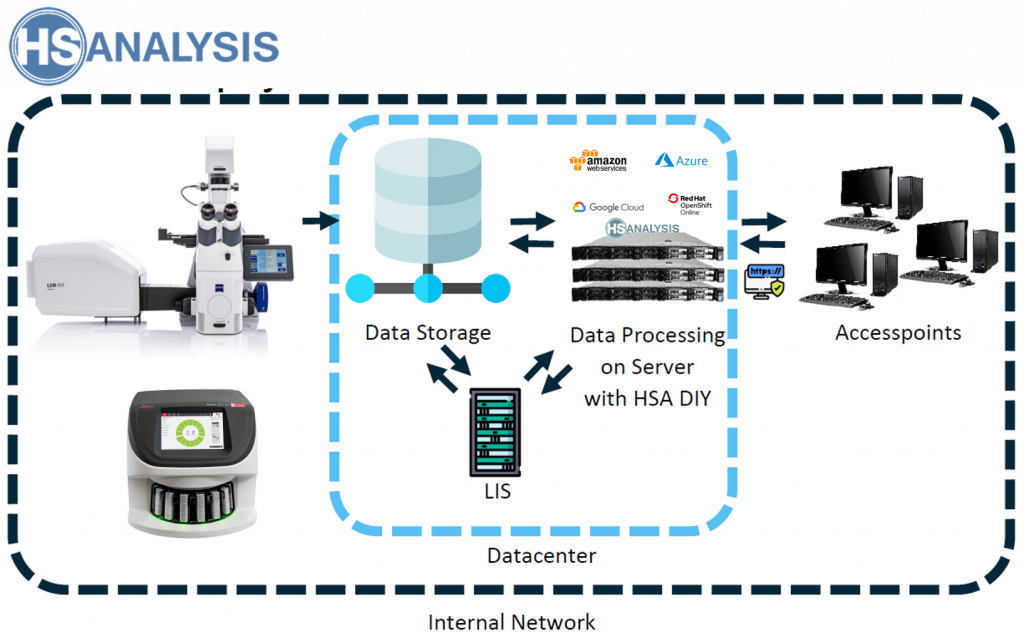

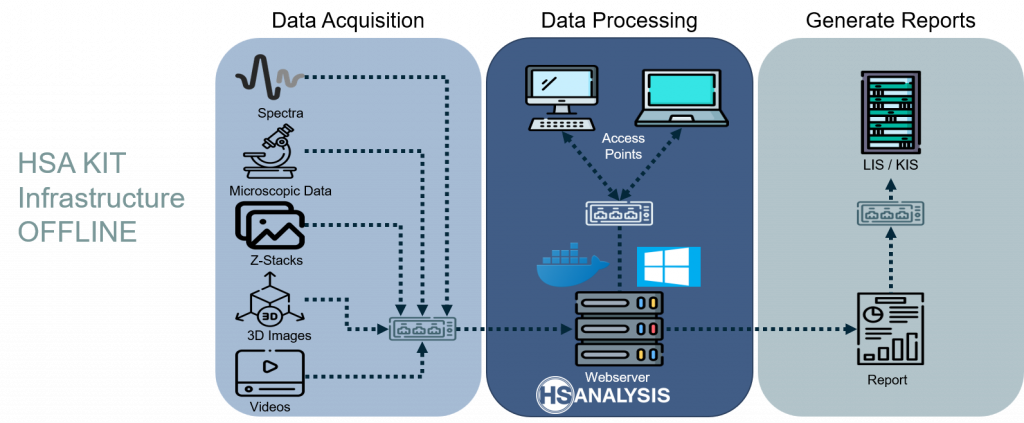

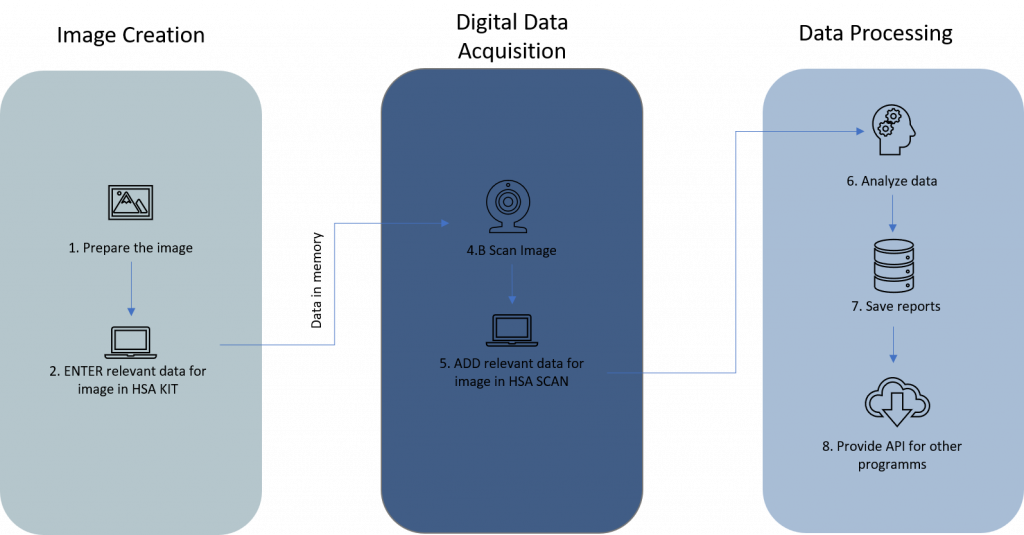

However, just identifying and analysing specific structures in a complex procedure might not be enough in cases like fungi fermentation. Despite having numerous industrial uses, the process from cultivation to product extraction is quite laborious because the overgrown hyphae not only obstructs the sensors and lead to unreliable measurement results, but also makes the broth more viscous. The optimum response to this issue would be to analyze the intricate process using AI software that mimics the physical process’s blueprint and provides the precise controlled conditions required for the operation. A digital twin would enable the seamless integration of several processes that affect the outcome. Furthermore, real-time data from sensors and other sources can be monitored to give a complete picture of the industrial process. Operators can spot abnormalities, pinpoint inefficiencies, and optimize the process parameters for increased performance, energy efficiency, and cost effectiveness by comparing the real-time data with the virtual representation of the digital twin. The HSA KIT software has an intuitive user interface and high-end professional annotation features to assure accuracy down to the last pixel. By standardizing processes, maintaining consistency, and promoting reproducibility, this can enhance the overall analysis process. The software focuses on object detection and recognition which are fundamental functions of standard image processing. Using image analysis, object detection algorithms identify and categorize things of interest, providing useful data for further analysis and decision-making. The FungiLyzer module focuses on detection of two most important structures for the study of fungal fermentation: Absolute precision in the detection of both structures. The object and background are readily differentiated by the model because of the pixel-level classification training which delineates pixels within an image There also might be visualisation problems associated with the appearance of the structures. Hence, for a better training, such structures would not be detected by the model. Below, an area of a much larger image that demonstrates the true outstanding object detection quality that HSA KIT is capable of achieving is shown. The images below may be zoomed in and out, and there is a slider that can be moved from left to right to improve and enhance the viewing experience. After the model has been trained and the project has been completed, the HS Analysis software provides the information required to understand the results in a sheet format, including the name of the files, the number of objects (structures) such as hyphae and vacuoles, the dimension of the analyzed areas in square meters within specific Base ROI (Region of Interest) area. While a basic model provides a general or broad overview of the subject matter, giving a high-level understanding without delving into the specific details or variations within the structures; the more customized module takes into account the diverse subtypes within each structure, ensuring that the results obtained are more refined and accurate. In the image below, hyphae are further characterised into three classes: The naturally occurring fungus are the source of biopesticides, which have been shown to be successful in lessening the damage that plant diseases, pests or weed do to crops. Since they don’t leave toxic residues in the soil or water sources, fungus biopesticides are also a more environmentally friendly option than chemical pesticides. Moreover, the process of fermentation involves the use of renewable raw material i.e. glucose. FungiLyzer may detect any anomalies or differences in the fermentation process by evaluating images of the process, enabling for early intervention and prevention of potential inconsistencies in the process. This not only improves workflow efficiency but also minimizes the danger of economic losses for companies. FungiLyzer also delivers real-time data and insights, allowing for informed decisions and the optimization of culture procedures for maximum efficiency. Analysing samples and digitalisation of the slides have never been easier before. HSA KIT provides an unparallel experience to its customers, who want to keep up with todays‘ „better“ alternatives and achieve higher efficiency in their workflow. The HSA team does all that is possible to please its clients, from the installation and integration of the software to the limitless support and upgradation. AI based analyses using HSA KIT would provide: We understand the importance of having accurate and efficient slide analysis software. That’s why we offer a range of features to help you achieve your goals. AI based analyses can be way more efficient, however it can only act as a supportive tool to human expertise and never be a complete alternative. AI algorithms have the tendency to produce false positives and false negatives, and may have trouble adapting to a data that deviates from training dataset. With our advanced technology and expert team of professionals, we are confident in our ability to deliver top-notch slide analysis services that meet the unique needs of each individual client. Whether you’re looking for a one-time analysis or ongoing support, we have the tools and expertise necessary to help you achieve your goals. Strong numerical computing programmes can be used for data analysis, modelling, and simulation. Despite the fact that they have a wide range of industrial uses, there are a number of reasons why they might not be suitable for predicting scale-up in industrial processes.

HSA KIT

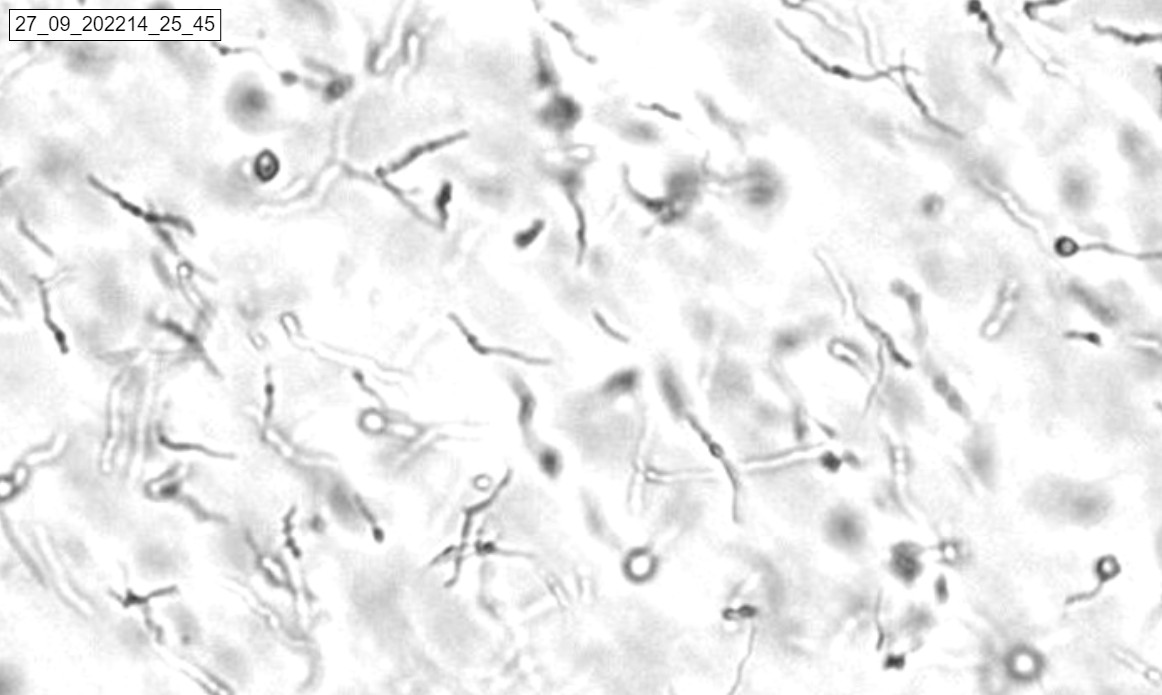

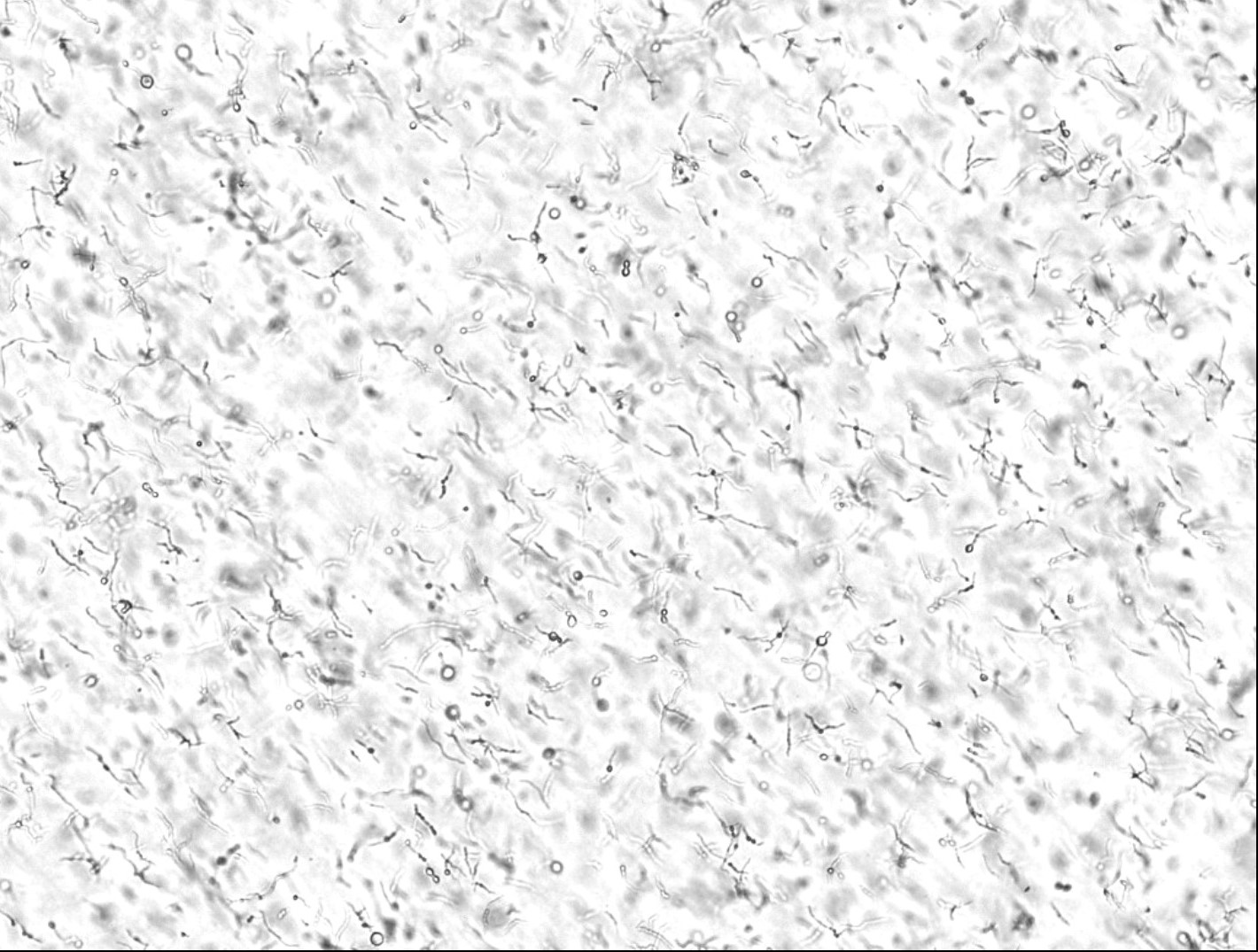

Zoom-out view

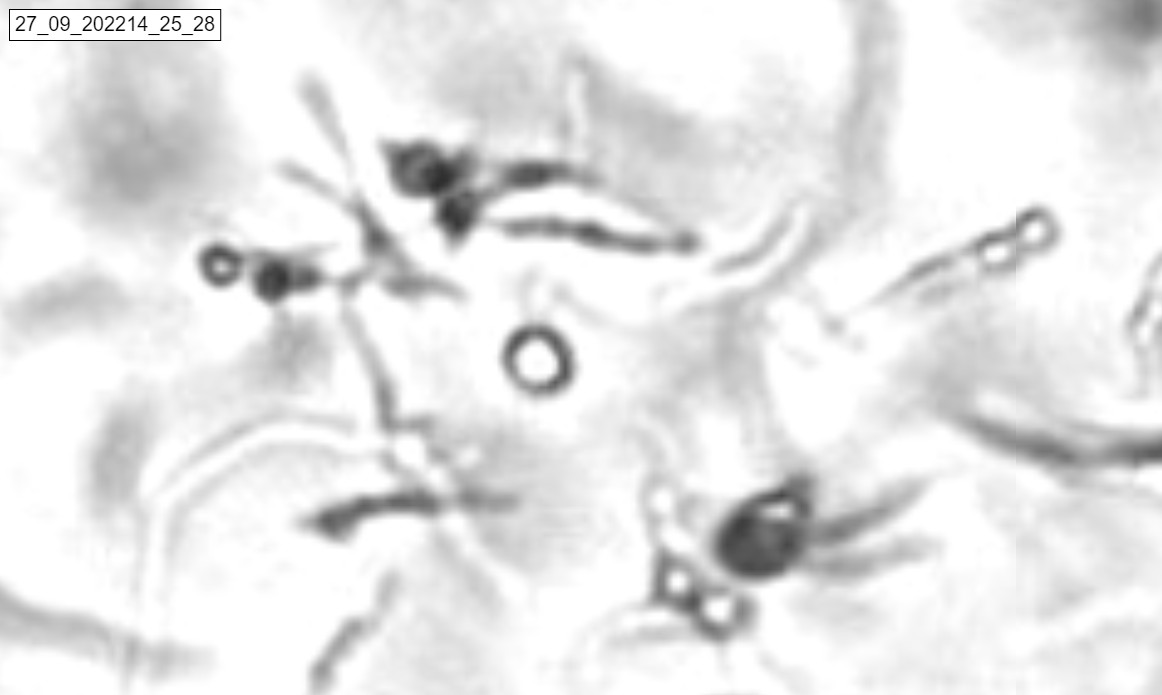

Zoom-in view

True Negatives

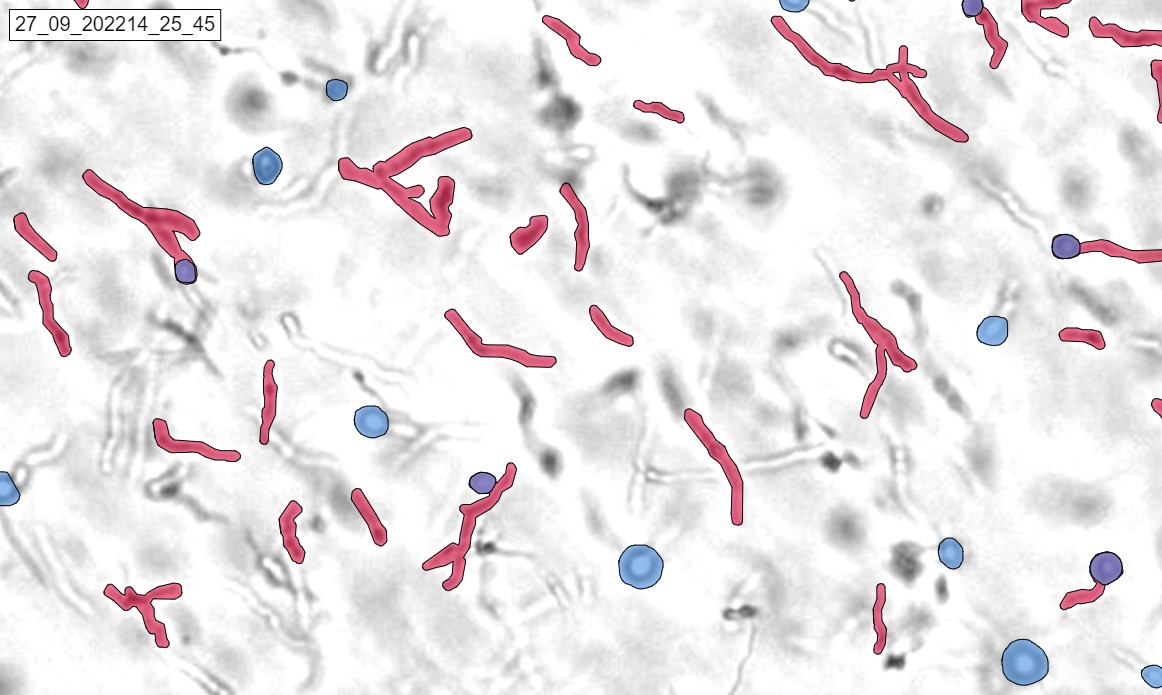

An example of detecting hyphae and vacuoles.

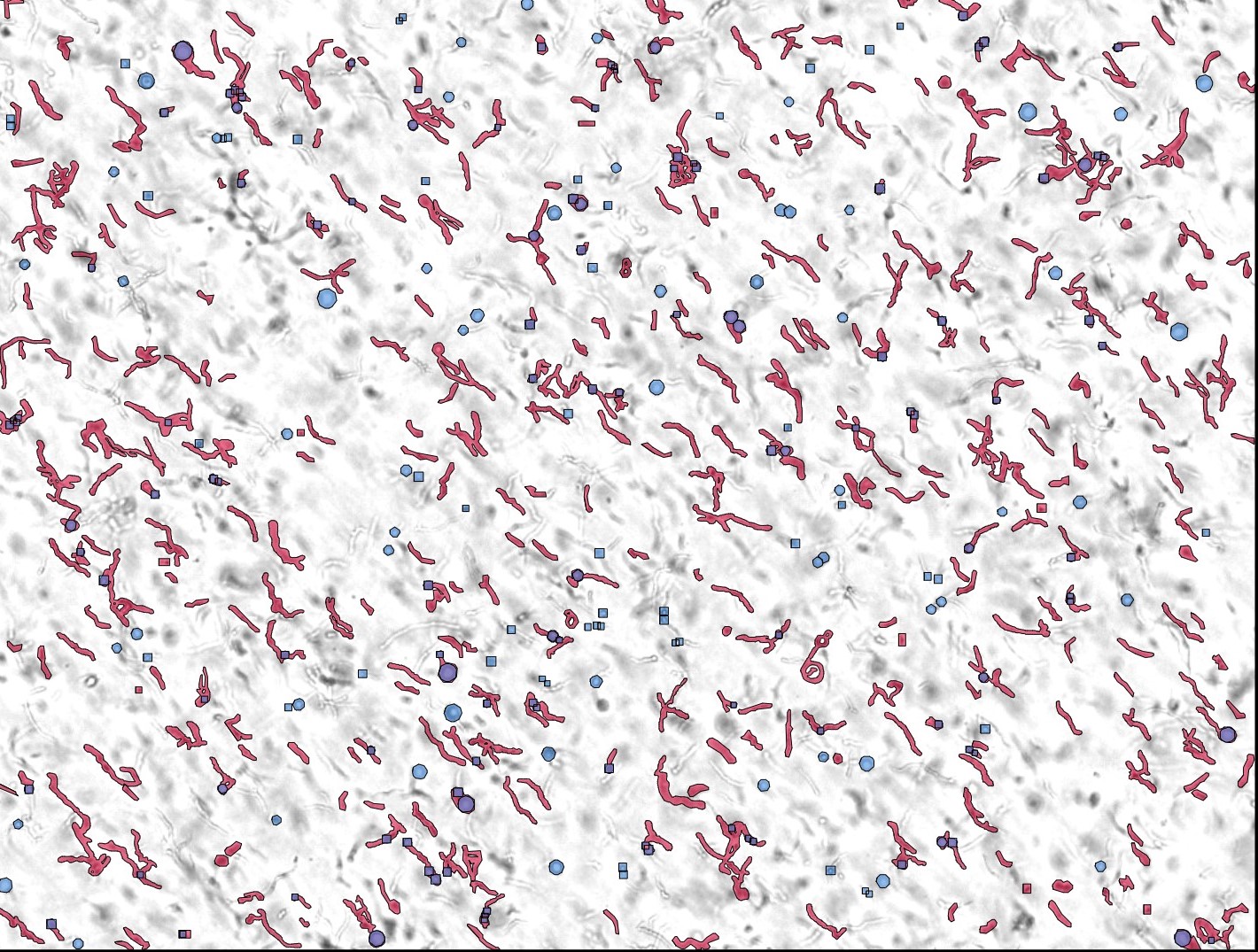

Zoom Out view of the whole image.

True positive hyphae

True positive vacuoles

Detecting Hyphae with three sub-classes.

Biopesticides: Real world Application

Workflow with HSA KIT

Better than alternative softwares