Motivation

Many manufacturing lines currently lack a digital twin that can accurately predict the outcome based on input parameters. As a result, fitting parameters again requires a time-consuming trial and error process. In the case of glass manufacturing, conventional stochastic models have proven inadequate in predicting outcomes. However, through our project, we are developing a groundbreaking AI system that can accurately forecast manufacturing line outcomes solely based on input parameters.

Our Aim

Our aim is to develop an End-to-End deep learning model that is able to predict the parameters your manufacturing line based only on the desired shape you want to manufacture.

Through that manufacturing experts will be able to focus on tasks that really require their expertise.

Current Results

Our ongoing development has resulted in a powerful predictive model that can determine whether a glass manufacturing line will produce broken glass, only based on the input parameters provided by our partners.

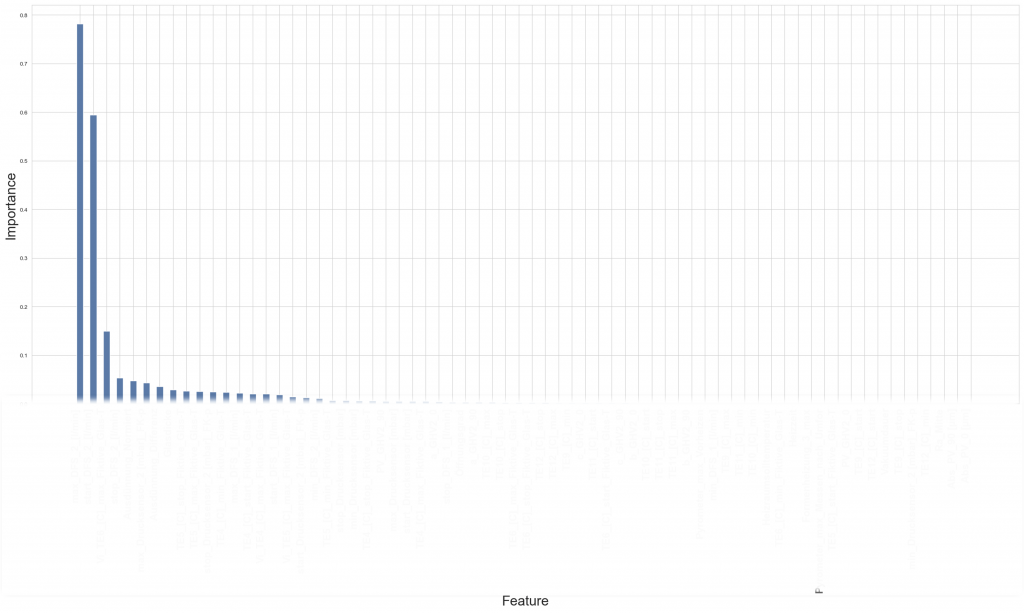

Furthermore, our data analysis capabilities allow us to offer valuable insights into the importance and impact of these input parameters on the final outcome.

The result of this analysis can be seen in the picture below. Only about 10% of the parameters used by our client really had an impact on the outcome!